THE TOASTER REDESIGN

We took apart a Proctor Silex Toaster and redesigned it in terms of manufacturability and assembly. We did this by reducing the number of parts needed and analyzing the assembly process. We also looked at the life cycle analysis that looked into how the components will be used after the toaster is finished.

HOW IT WORKS

Crumb Ledge: The small ledge only allows for a small amount of crumbs to fill up. The ledge then releases when the side is pulled out easily dumping the crumbs on the plate for cleaning.

Bread Slide: The slide allows the users to easily remove the bread and put it on the plate without the user having to even touch the bread. This is all done by the work of gravity.

Clear Front: The user is easily able to check on the doneness of the toast. This allows users to not burn themselves while attempting to get the fresh toast onto their plate.

What we did

Team:

Taylor Mau

Brian Xiao

Lama Alfulaij

Gaurav Asthana

Xiaohan WuRole:

Design EngineerDate:

Aug 2018 - Oct 2018Location:

Carnegie Mellon UniversityProcesses Used:

Disassembly, Customer Requirements, CFE, Brainstorming, LCA

MY ROLE

I took the lead in designing the final toaster form. I CADed the toaster as well as rendered it in Keyshot. I also helped everyone understand the engineering of the design with Gaurav. We helped make sure that the design was feasible and was mechanically and electrically sound. I helped make sure that we were on schedule and made the final revisions of documents to make sure that they were ready for submission.

DISCOVER

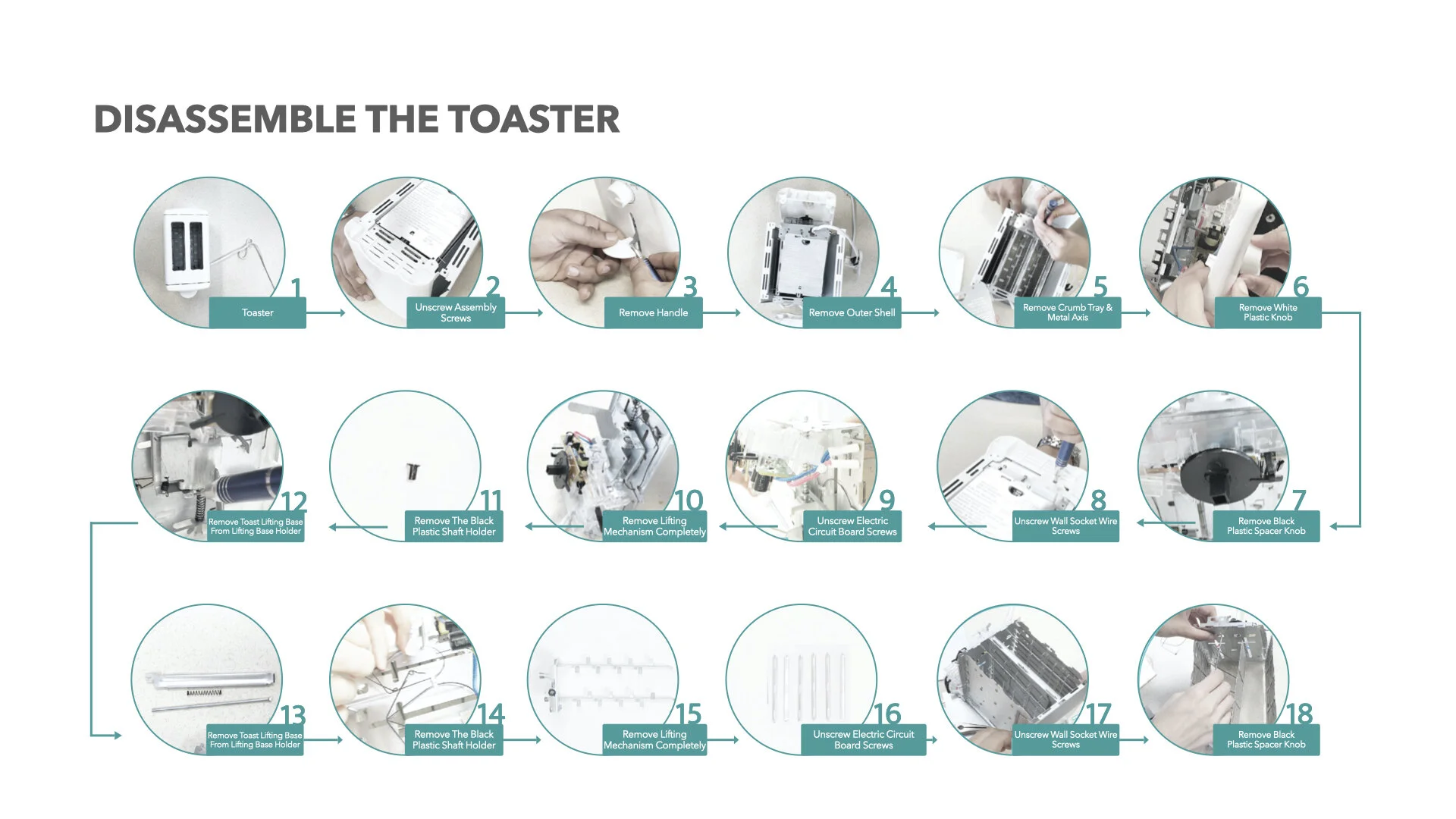

Disassemble the Toaster

In order to understand how a toaster works, we disassembled the toaster and then reassembled it. We documented each step of the process below.

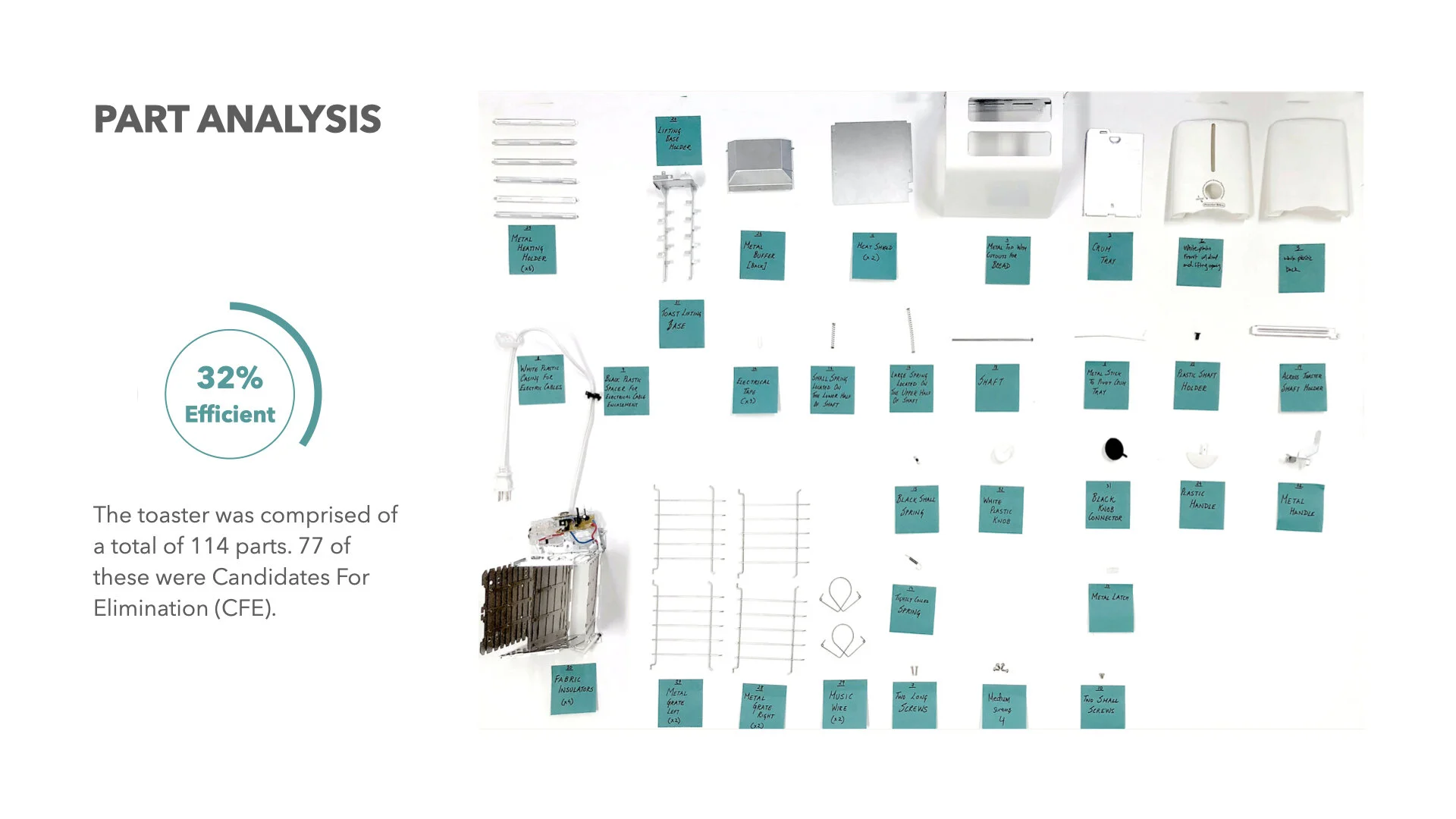

Toaster Analysis

We then analyzed each part to see if it was a candidate for elimination (CFE). To determine if it was a CFE, we asked ourselves three questions:

Does this part move relative to other parts?

Must the part be made of a different material?

Does the part need to be separate for manufacture or repair?

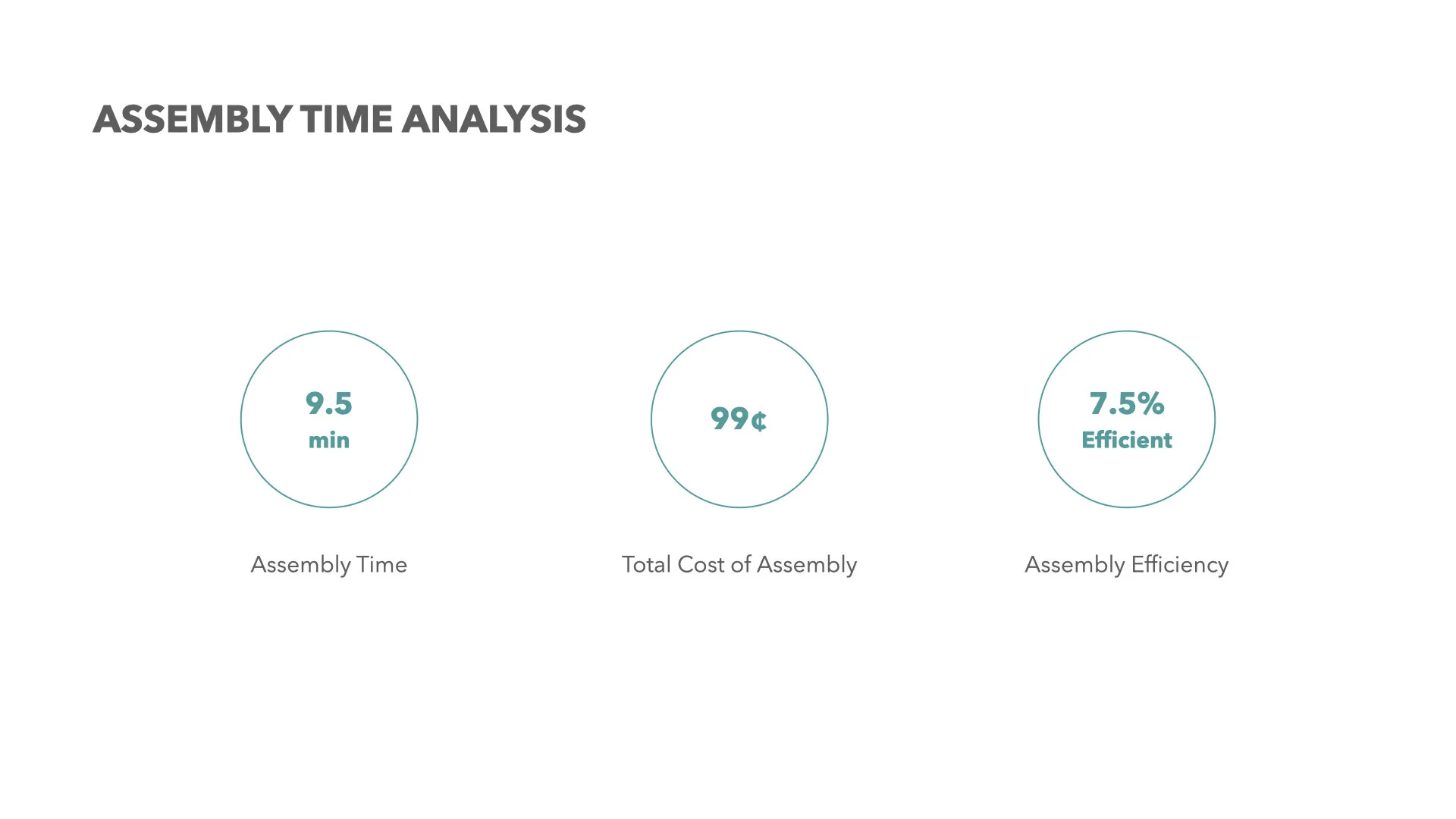

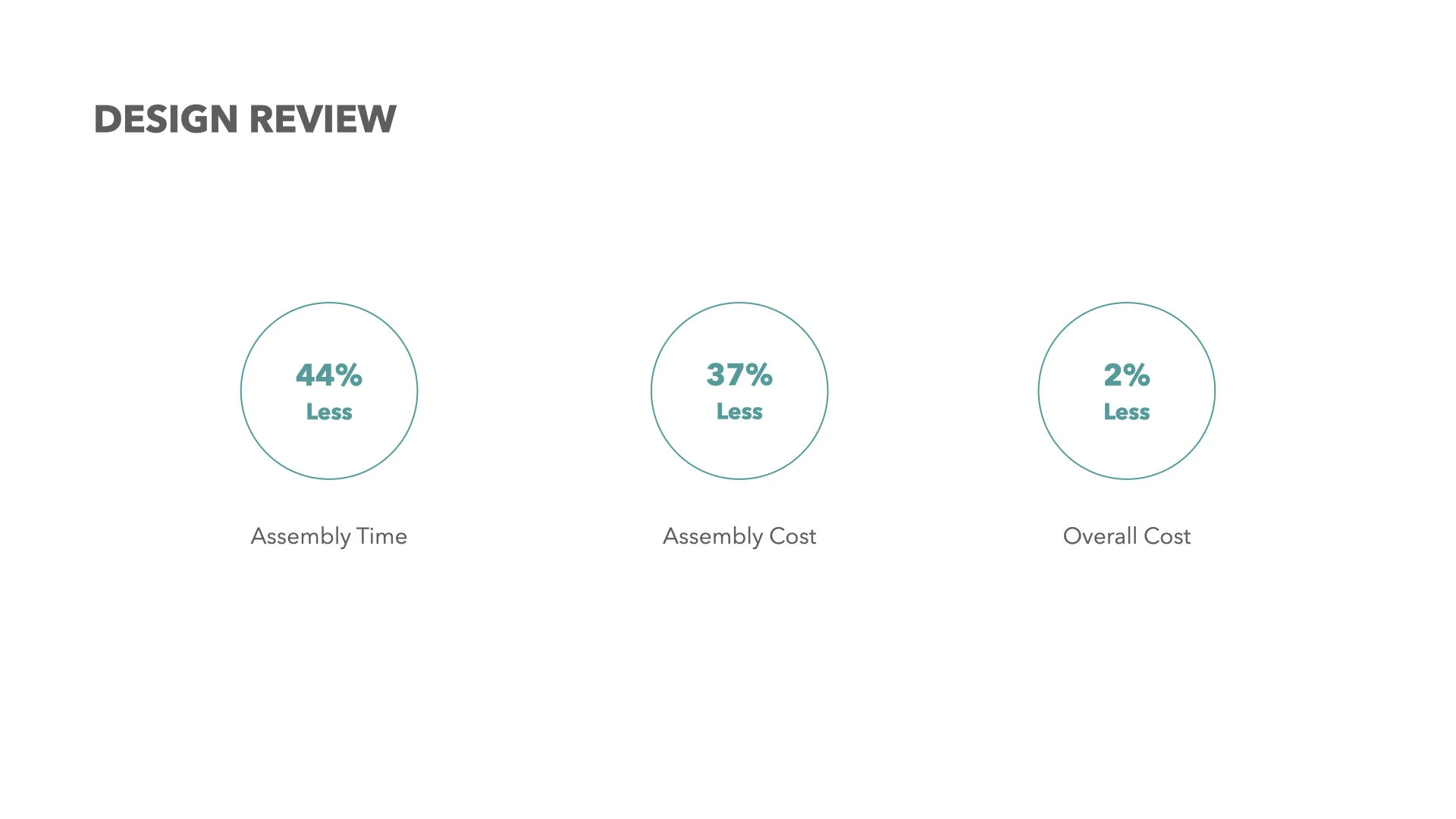

Current Toaster’s Assembly is Inefficient

The current toaster takes about 9.53 minutes to assemble costing about $1.

DEFINE

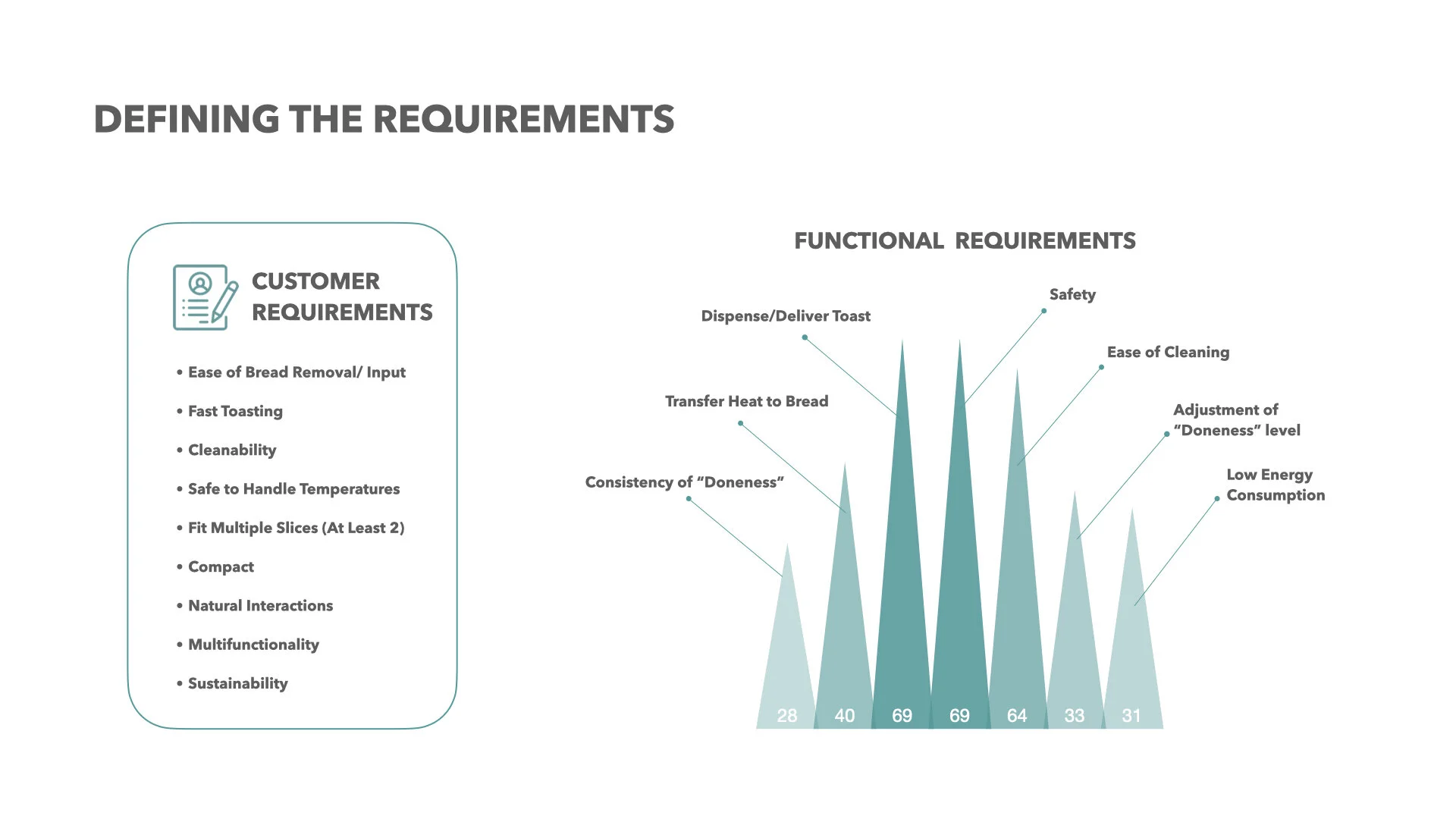

Essential Requirements of the Toaster

We then thought of the various requirements of a toaster and weighted them based on the customer requirements and functional requirements. We created a house of quality to determine the level of importance.

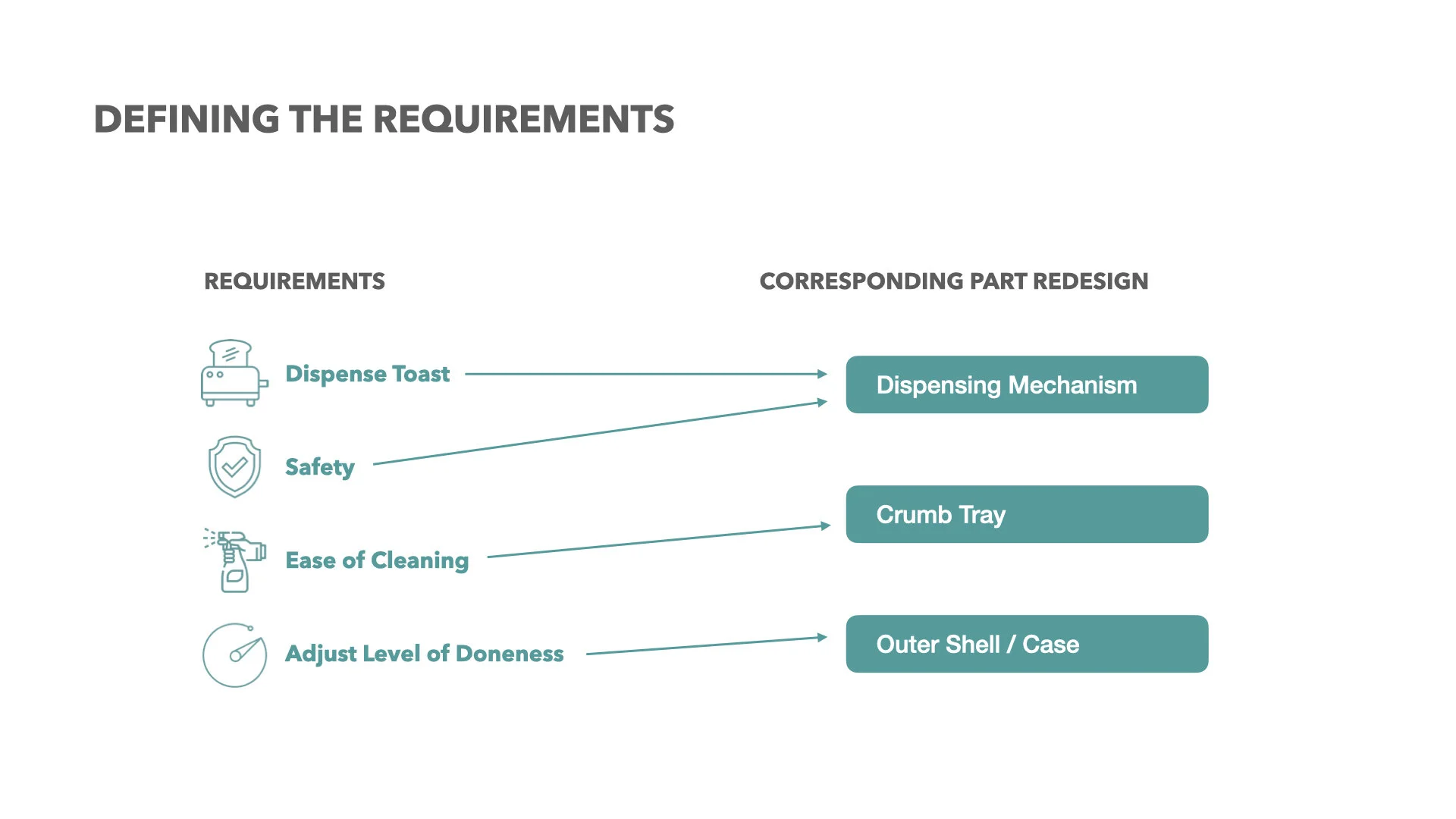

Redesign Implications Based on Functional Requirements

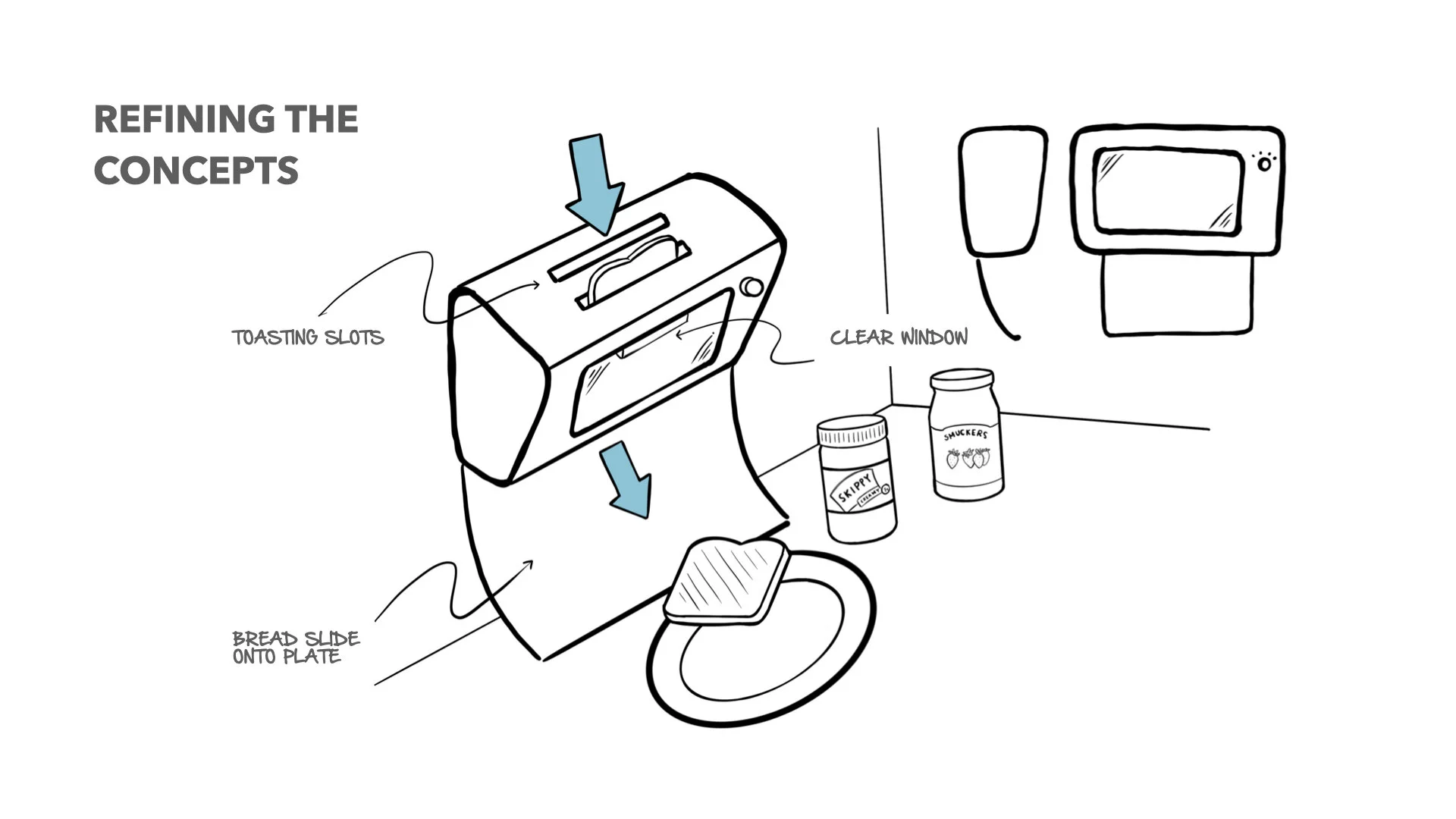

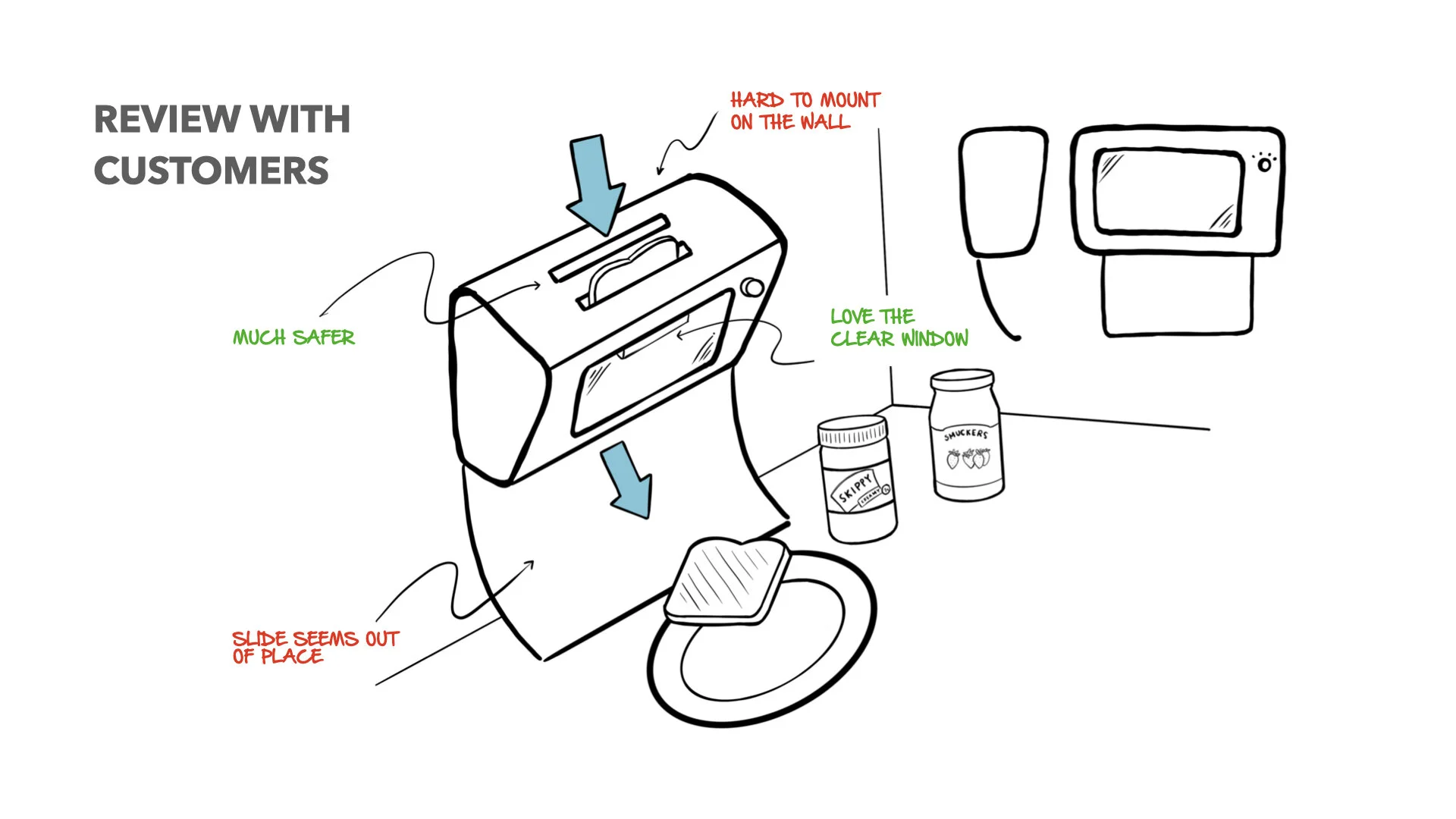

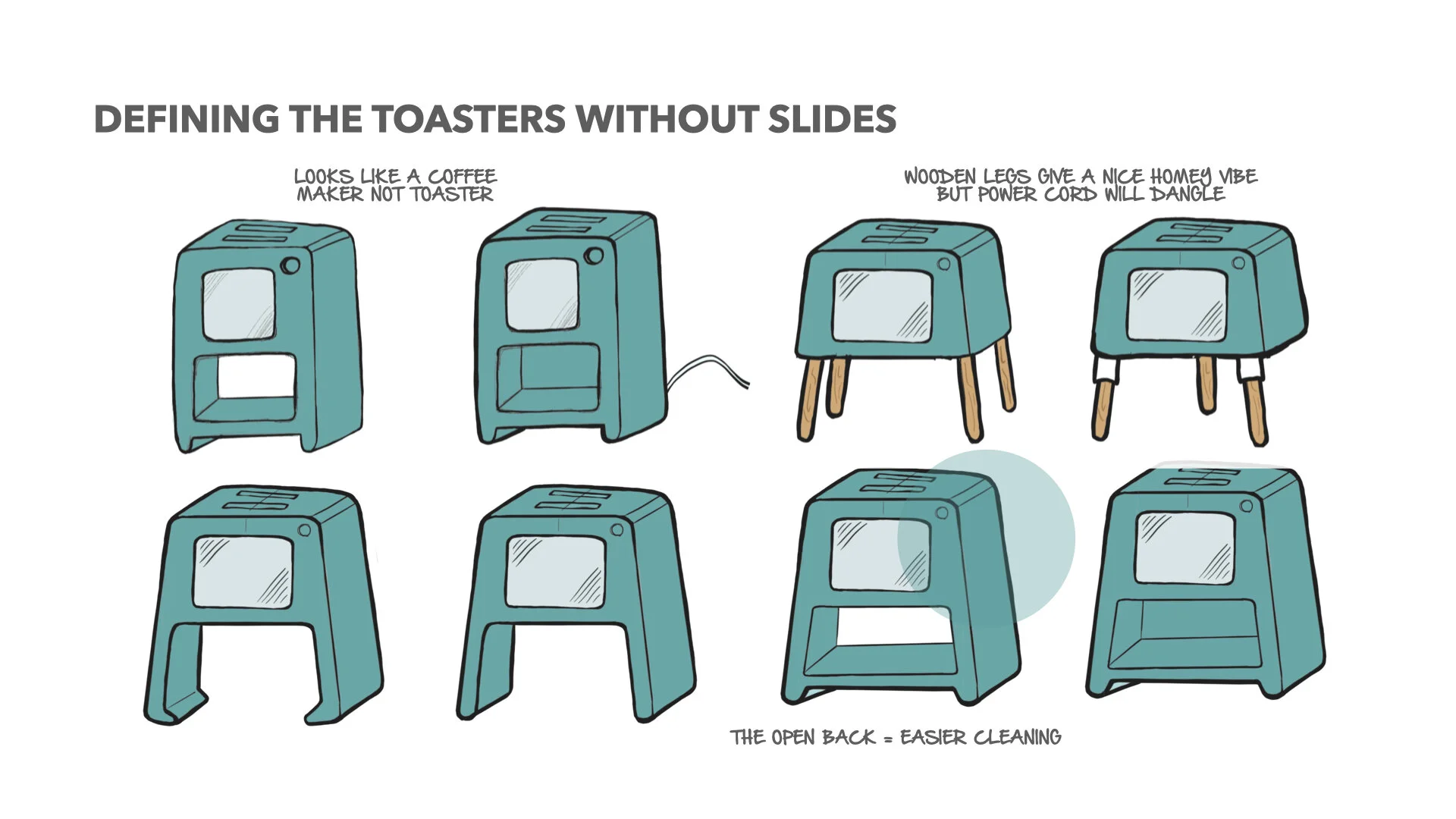

DEVELOP

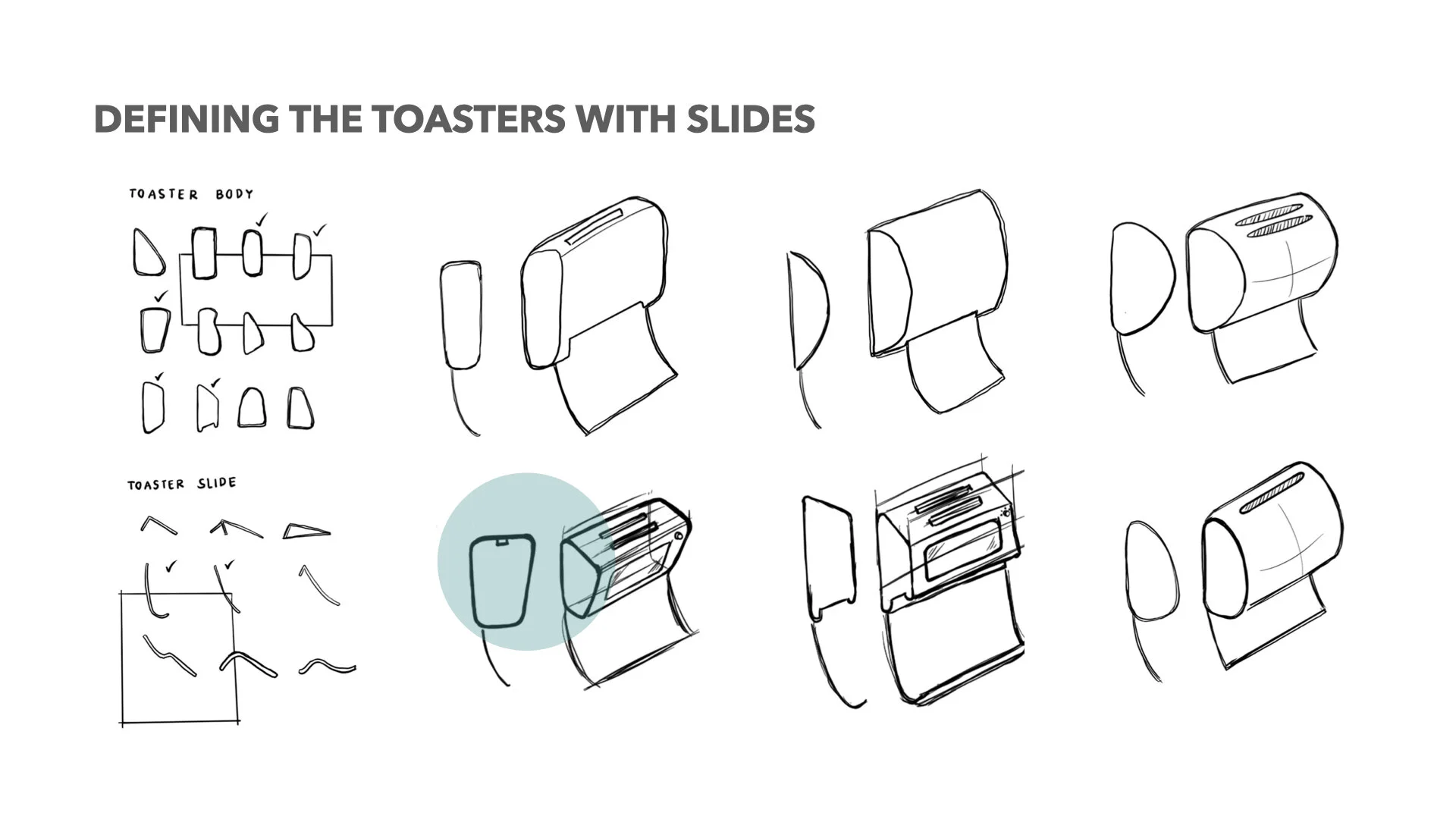

Brainstorming

We sketched out various methods of redesigning the dispensing mechanism, the crumb tray and the outer casing.

DELIVER

Our new design has a clear glass window allowing users to see how toasted their bread is. We have an easy handle to allow users to slide the bread in and out removing the need to stick your hand in the toaster oven. The bread drops straight onto the plate. We also removed the need for a crumb tray so that users will not need to clean out the toaster.