What we did

Role:

Prototyper, Electrical Engineer, Software EngineerDate:

May 2017 - June 2017Location:

Santa Clara UniversityTechnology Used:

Low Fidelity Prototyping, Rapid Prototyping, User Research, Laser Cutting, Arduino

The Ohmganizer - Resistor Sorting Drawers

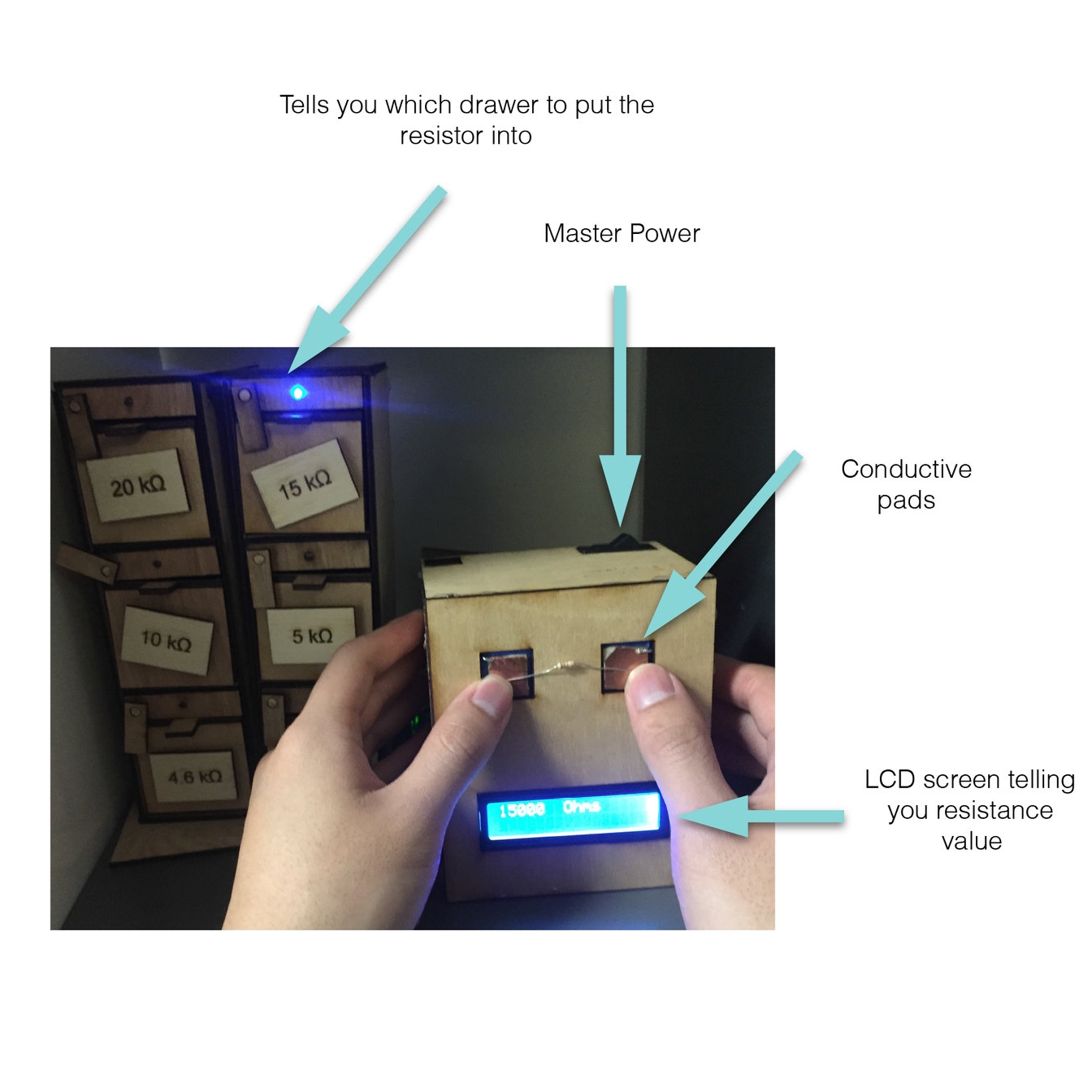

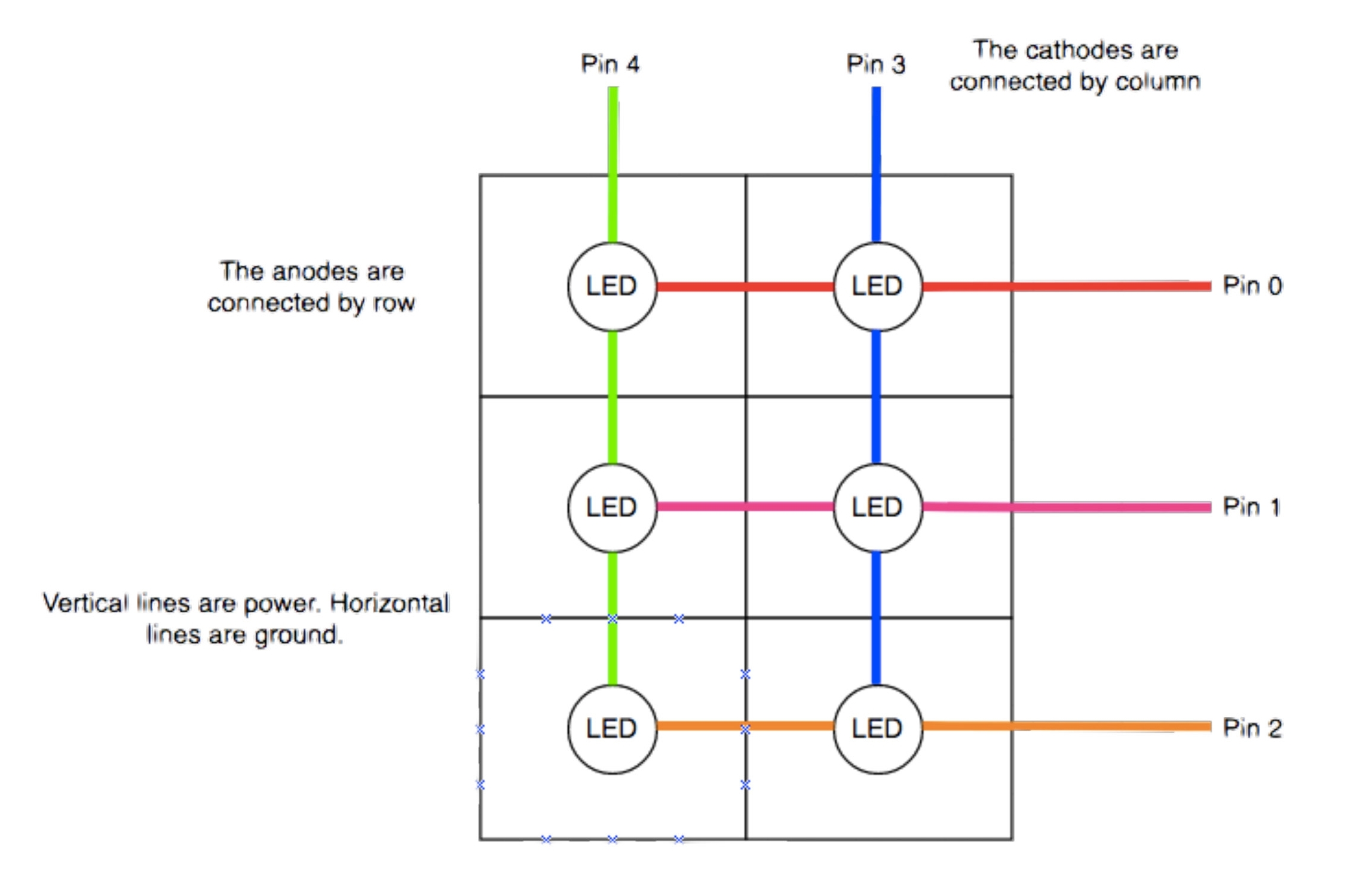

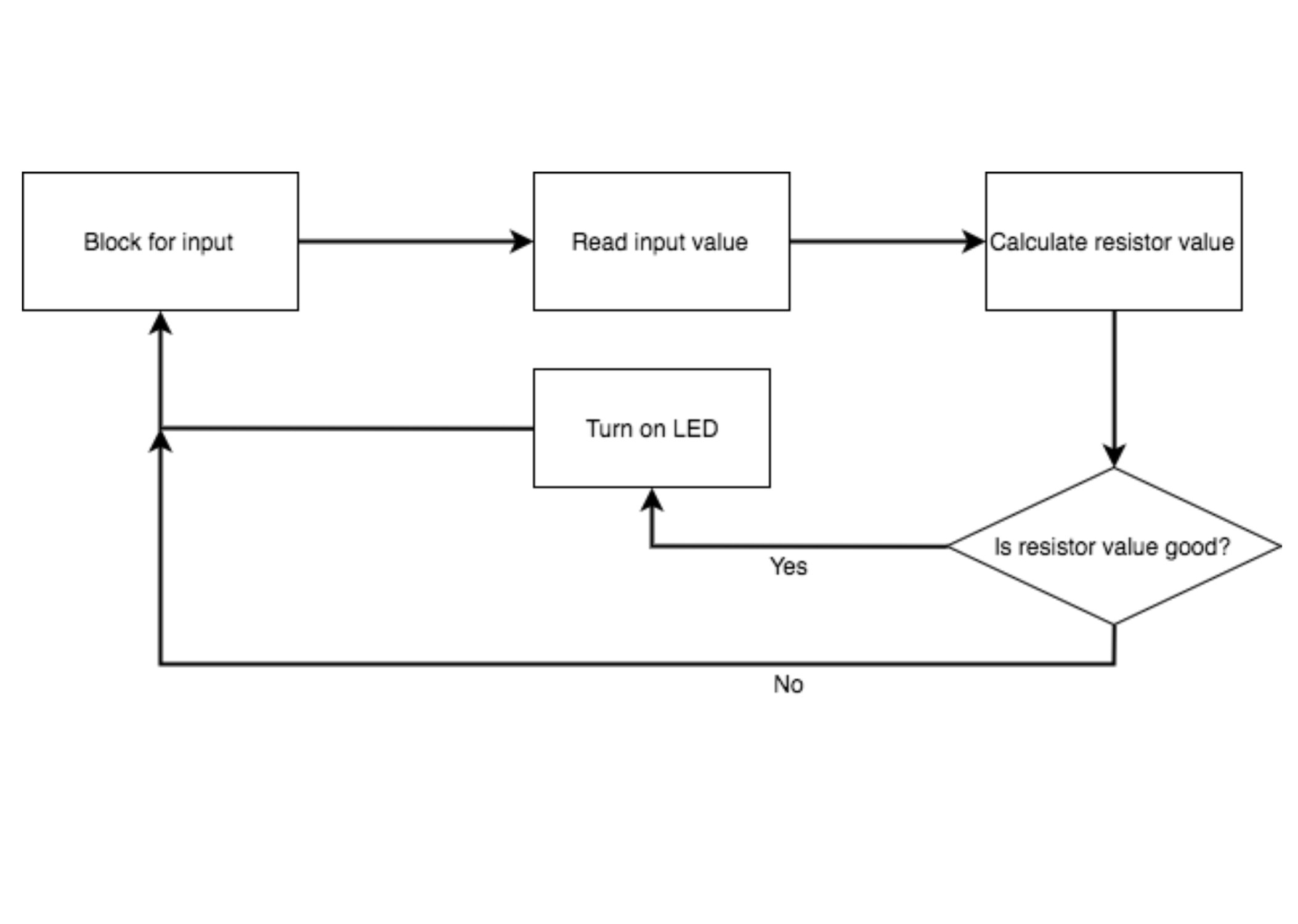

We redesigned the process of sorting components after lab by gaining empathy and insights through user research. We designed a smart drawer system that lights up the corresponding drawer with an LED when users place a resistor on the copper pads using an Arduino. Users are able to easily put the resistors in the correct drawer without having to think. This drawer saves components from being thrown away at the end of lab. Now, labs will be able to maintain their inventory of components.

Features:

Measures resistance easily

Displays resistor value

Lights up LED on corresponding drawer

Lockable drawers to prevent spillage

Removable resistance labels for modularity

MY ROLE

As the team leader, I made sure that we were always on task. I helped keep everyone motivated and make sure that everyone was passionate about the project. Because of my background, I was able to help on the software, hardware and mechanical aspects of this project. We all worked together on the discover, define and development phases.

DISCOVER

Identifying Target Markets

To start, the branch method was used to begin the brainstorm process. We started with the word ‘market’ and created ideas from there. We chose to focus on looking into Electrical Components and Snacks.

Bisociation Results

The team used different objects such as tiki heads, tables, and chairs in order to create novel innovations. For brevity, only the toothbrush bisociation will be covered. The team analyzed the functions of a toothbrush and came up with a list of product features. Some features include, waterproof, scrubbing, vibrating, modular, and portable. The features that the team wanted to focus on was the modular and portable aspects.

IDEATION - LOOK AT TWO VIABLE IDEAS

1. Electronic Component Dispenser

The Pains:

Difficult to organize components

Components often placed in wrong drawer - Easy to knock over drawer

Bisociation: Using a toothbrush

Clean and Organized

Portable - The team expanded off of the idea of being portable which lead them to thinking of a customizable vending machine. Having modular drawers that can seamlessly interlock would allow users to add on new drawers as needed. Each drawer a single value to provide an organized workflow. When the user returns the components, the dispenser will measure the values to put them back in the corresponding drawers.

2. Custom Instant Ramen Bowls

The Pains:

Difficult to get good snacks around campus

No customized food from regular vending machines

Bisociation: Toothbrush

Involves water

Human operated and human decision-making required - The concept behind this idea is to have a dispenser for users to buy a serving of instant noodles and customize their meal by selecting various dehydrated toppings based off of the amount paid. During the topping selection process, a hot water kettle would heat up to provide a method to cook the instant noodles. The user would then pour hot water in and wait the requisite amount of time.

DEFINE

Problem Solution Analysis - Chose electrical component dispenser

The electronic component dispenser was chosen since the market for this product is more niche. The pros and cons of this product are of greater impact since this problem affects every engineering student. The electronic component dispenser is technically difficult to implement, with added complications of having a wide range of components. Additionally, the process of reading each resistance value is slow. The modular interface may also fail. However, this product would solve the otherwise painful process of organizing components while preventing component spillage and components going into the trash. The dispenser also allows for a centralized storage location and saves the user time in the sorting process.

Validation

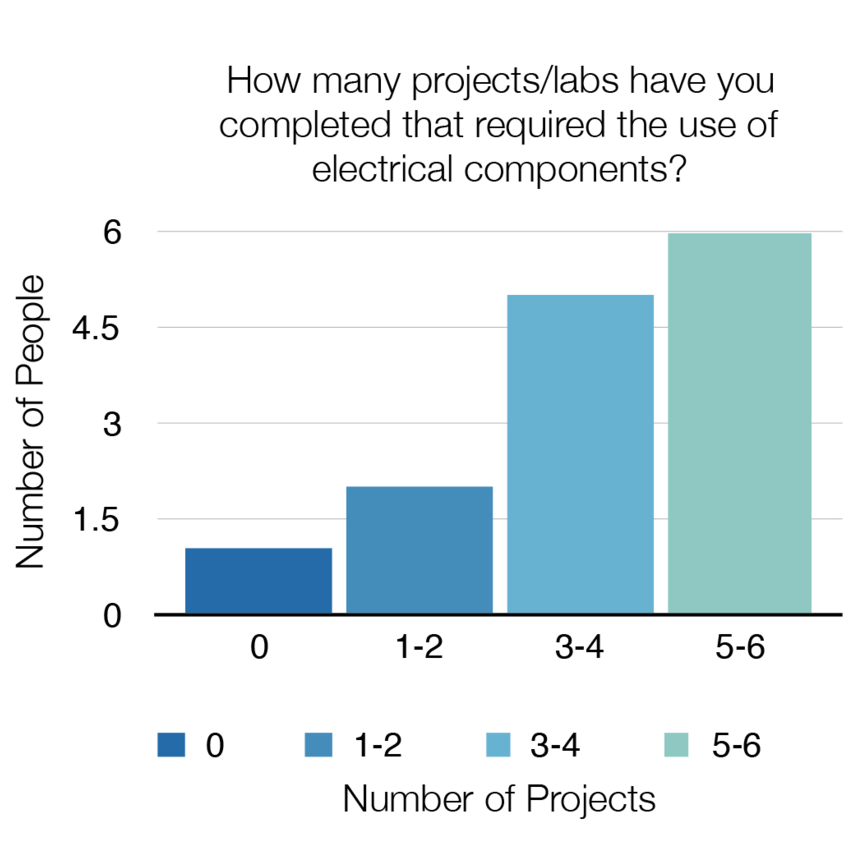

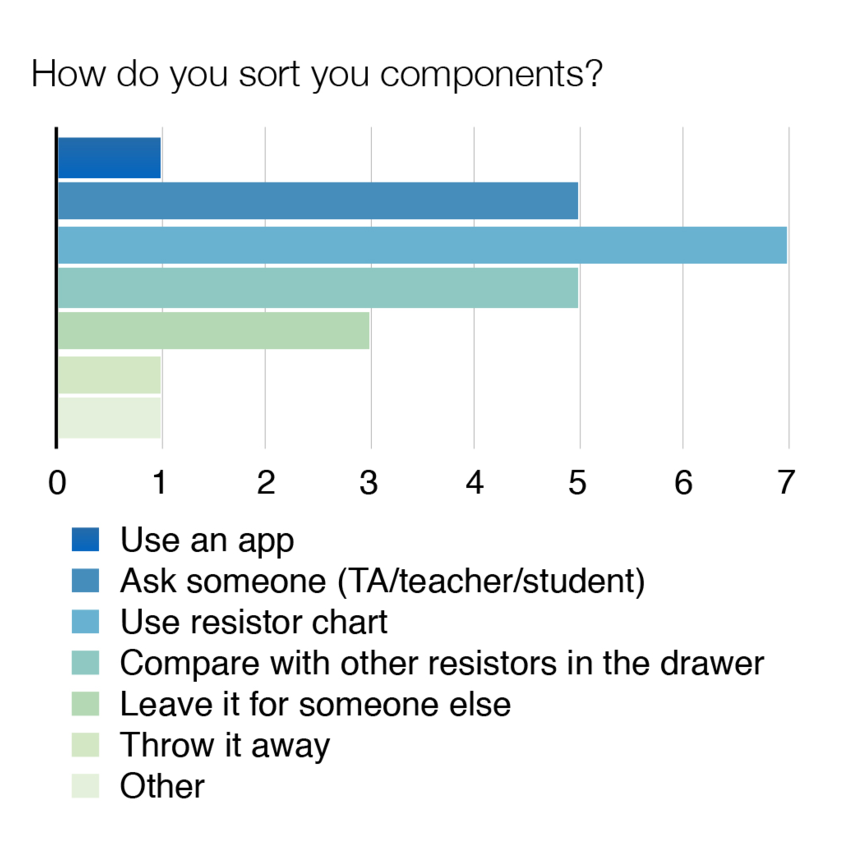

We validated the customer profile by researching the target market. Research was done by providing a survey. The survey asked a variety of questions designed to target the usage and needs of the customer. The results of the survey revealed that 40% of moderate-heavy users of electronics would use a resistor sorting device. An additional 40% would potentially use such a device. In this niche market, there is some demand for this product. We also saw that many students admit to having trouble finding the value of the resistor and throwing the components away.

DEVELOP

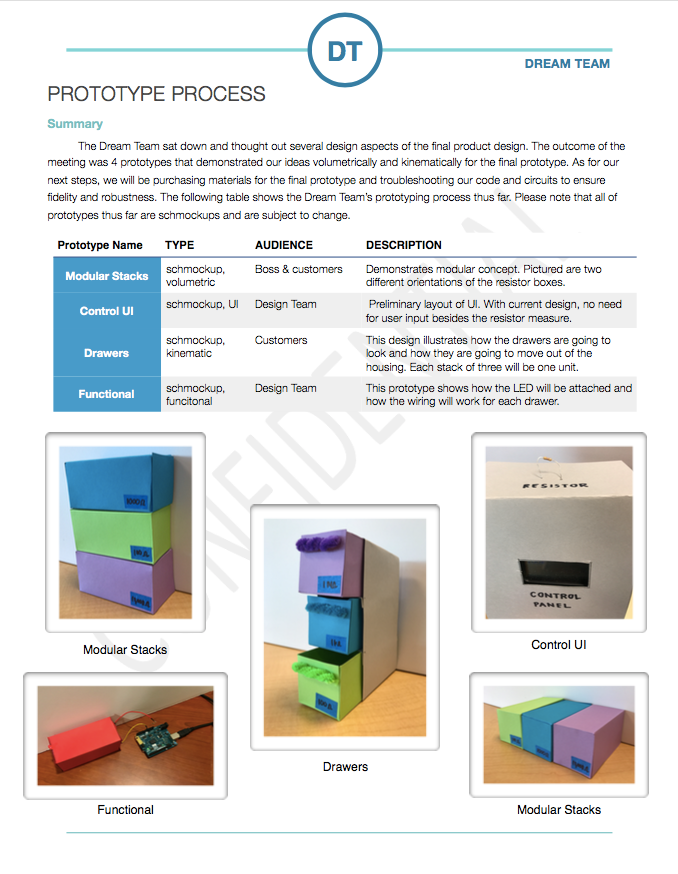

Prototype

We thought out several design aspects of the final product design. The outcome was 4 prototypes that demonstrated our ideas volumetrically and kinematically for the final prototype. The table shows the purpose of each prototype and a brief description.

Validation Interviews

Yohannes Kahsai - Electrical Engineering Lab Manager

Kahsai responded that the product is a useful tool for laboratory work. Additionally, this idea can further be expanded to include other electrical components like transistors, capacitors, and inductors. Ultimately, Kahsai said that he would buy the product.

Robert McDonald - Lab TA

McDonald suggested conductive pads in order to measure the resistance value instead of inserting it into a breadboard. This would increase usability. Additionally, McDonald said that he would use the drawers.

Dr. Andrew Wolfe - Mechatronics Professor

Dr. Wolfe provided the suggestion to further subdivide each drawer so each drawer holds two resistor values instead of one. The main concern with the current design was that it would not hold enough resistance values. Dr. Wolfe further stated that he has been using the same box of resistors for years because he does not want to rewrite labels. This shows the customer wants a simple system that just works.

DELIVER

Final Functional Prototype

THE TEAM

From left to right:

Justyn Li - Senior Mechanical Engineer Taylor Mau - Senior Electrical and Computer Engineer

Derrick Chan - Senior Computer Engineer.

Future Steps

Some additional features that we wanted to include for future iterations of this product include:

• Voice control

• App integration

• Hardware programming of resistor drawers

• More modular design

• Automatic sorting

Final Functional Prototype — Design Summary

The Ohmganizer has several key features

• Modular drawers with individually addressable LEDs

• Locking mechanism for drawers

• Conductive pads to read resistance values

• LCD screen to relay information to the user

• Master on/off switch

SOFTWARE

HARDWARE

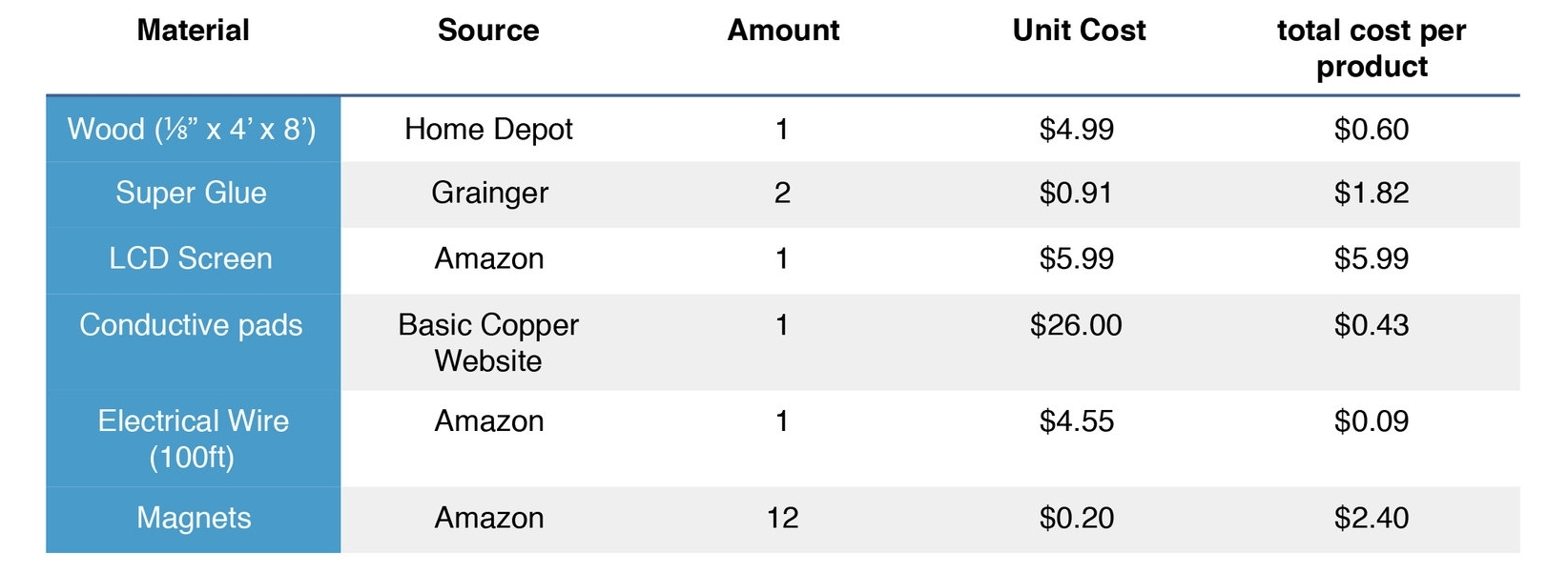

Cost Breakdown

Product Viability

The team cannot compete with a traditional set of resistor drawers. Those drawers are cheaper so many will choose our competitor’s drawers. Instead, the team will sell the schematics for $9.99. The benefit of selling the schematics is that there are no material costs, labor costs, or transportation costs.

Fixed cost = $100 for employee salary and electricity cost

Price per unit = $9.99

Cost per unit= $0. We are selling the IP

$100/($9.99) = 10 units to break even

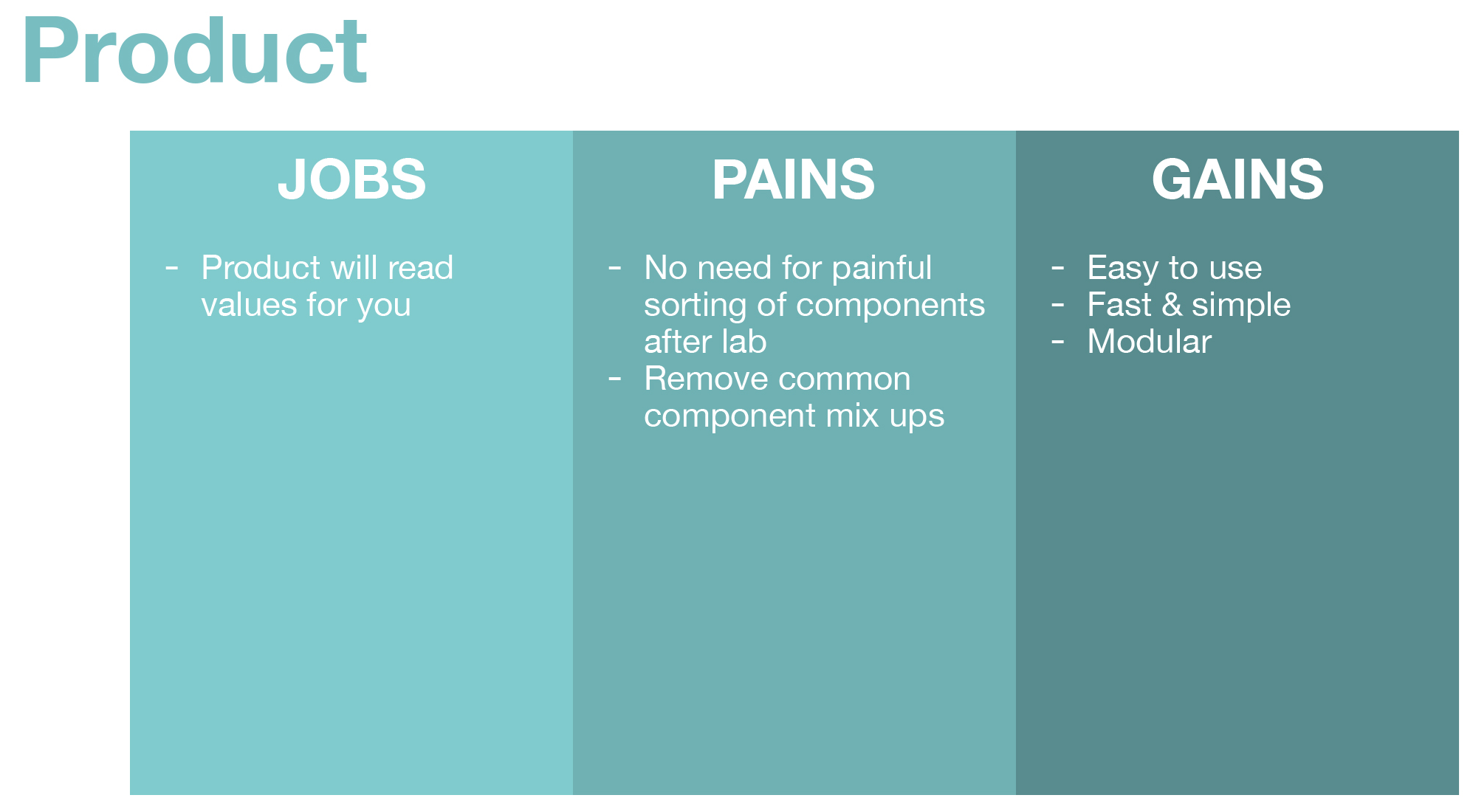

Value Proposition

The value proposition for the resistor sorter/dispenser is to provide an easy, all-in-one system to properly sort and size resistors. Customers should use this product because this system provides the means and tools to prevent massive piles of unsorted resistors. This product will be a tool to streamline workflow by providing a centralized repository for resistors.